The Know How of construction of the Commercial Laboratories makes it possible to take advantage of all the advantages offered by the specific lighting conditions for each region, on the other hand, the use of Temporary Immersion Bioreactors (BIT) reduces costs and increases production volumes in limited physical spaces, the combination of these factors constitute a guarantee in obtaining high quality plants at low cost. The Bioplant Center of the University of Ciego de Ávila has worked on the development, implementation and transfer of conventional micropropagation technologies since 1982. Temporary Immersion Bioreactor prototypes have been established as an important complement and superior technology in the massive propagation of various botanical families of ornamental, fruit, ornamental and agricultural interest plants in general. The fundamental characteristics of technology transfers related to the massive propagation of plants under these premises are to reduce costs and increase the production volumes of high-quality propagules. For this, natural light is used in the growth chambers, simple and inexpensive culture media, chemical sterilization, the use of the temporary immersion technique, as well as the qualification and professional improvement of the specialists together with international quality standards that make this a distinctive process. Characteristics and advantages of the project. The Commercial Laboratories designed present a construction know-how that makes it possible to take advantage of all the advantages offered by the specific lighting conditions for each region. This allows the costs of using solar energy to be lowered. They also present simple designs adapted to the demands of the work so that it allows an inter-relationship or flow between the premises or departments that have a direct participation in the production process. This allows adequate comfort for workers as well as easy handling by specialists during commercial operation. The Laboratory's infrastructure allows for short-term production increases, as well as products with a quality comparable to those required by the international market. Plants may be certified for genetic stability (true-type) and disease free. It also includes a Department of establishment and scaling, meristem cultivation and in vitro conservation of germplasm, which will allow the massive propagation of plants in Temporary Immersion Bioreactors, somatic embryogenesis, conservation of stem tips, sanitation of plant material. . Additionally, the cryoconservation of plant tissues and the obtaining of new varieties of ornamental plants can be implemented as a distinctive product in the productions of the Commercial Laboratory. Technical rationale. The design, construction and commissioning of the Commercial Laboratory for the mass production of plants through the use of Temporary Immersion Bioreactors will be carried out in the following work stages: Design of the Commercial Laboratory for Mass Propagation of Plants: consulting is included during detailed engineering, as well as advice for the purchase and assembly of equipment and furniture. Start-up of the Commercial Laboratory for Massive Propagation of Plants: this includes advice for the validation of the start-up of the Laboratory, technology transfers, specialized training for management personnel or specialists or workers in general at the Laboratory. Operation of the Commercial Laboratory for Massive Propagation of Plants: the improvement and training of the personnel of the Commercial Laboratory for Massive Plant Propagation is included. Expected benefits. Increase in production, productivity and product quality that makes it possible to reach a larger national and international market for the commercialization of seedlings in any of their growth phases. Obtaining and introducing new varieties of plants that are more attractive to the market, such as those of high value for human consumption due to their quality, yield, or resistance to pests and / or diseases, as well as for crops that show ornamental, forestry interest. or horticultural. Additionally, variations or variability in the crops of interest may be obtained and improved varieties can be established in the market, which will allow increasing the biodiversity of the plants or products that will be offered in the new Commercial Laboratory in order to reach a position of relevance in the market. National and international. Application experiences. The technology transfers of our products are used successfully in the following national and international institutions: National: Commercial laboratory for the massive propagation of ornamental plants. University of Ciego de Avila, CUBA. Commercial laboratory for mass propagation of fruit plants. Bioplants Center. University of Ciego de Avila, CUBA. Biofactory for the production of bananas. National Seed Company. Camaguey, CUBA. Biofactory for the production of bananas. National Seed Company. Ciego de Avila, CUBA. Commercial laboratory for the massive propagation of ornamental plants. Provincial Communal Company. Ciego de Avila, CUBA. Pasture and forage tissue culture laboratory. Sancti Spíritus, CUBA. Culture and tissue laboratory. Las Tunas, CUBA. TROPIFLORA culture and tissue laboratory, Havana City, CUBA. International: Federal University of Santa Catarina. BRAZIL. CENARGEN / EMBRAPA. Brasilia, BRAZIL. CNPMF / EMBRAPA. Cruz das Almas, BRAZIL. CPERZUCAR. Pirazicaba, BRAZIL. Peñaflor Production Center. San Gil? Bucaramanga, COLOMBIA. Plant Biotechnology Laboratory. Eastern University. Black river ? Medellin Colombia. Plant Biotechnology Laboratory. Agronomy faculty ? University of Montería, COLOMBIA. CBIOCA. ESPOL? Guayaquil, Ecuador. Technical University of Esmeralda (UTEC), ECUADOR. Plant Biotechnology Laboratory. Technical Institute of Costa Rica (ITCR). San Carlos Headquarters, COSTA RICA. Plant Biotechnology Laboratory. Phytotechnics Area? Autonomous University of Chapingo, MEXICO. Plant Biotechnology Laboratory. La Molina University, Lima, PERU. Scientific Research Council (SRC). Kingston, JAMAICA. Tissue culture laboratory. University of Belize, BELIZE. Godollo Agricultural University. HUNGARY. SBW International, BV. THE NETHERLANDS. PLANTECK. Biotechnologies. (Québec), CANADA.

Each culture presents its specifications in terms of handling and care in each of its phases, from implantation to hardening, our Center offers propagation technical instructions either by conventional techniques or through the use of Temporary Immersion Bioreactors ( BIT) of the following species: Forest: The rescue of forest species of commercial interest is one of the priority lines of biotechnology as a basic tool in supporting the improvement of plus trees. In this way, it accelerates multiplication rates and participates in reforestation programs in areas with major deforestation problems as a way to maintain the balance of the natural ecosystem. Ornamentals: Ornamental plants are the ones that have been the object of the greatest commercial micropropagation in the world. It is noted that the number of commercial laboratories in the plant tissue culture industry in Europe is increasing at the rate of 3.5 times per year. Some prestigious Western European firms recognize that Cuba can obtain close to 300 million USD annually from the sale of ornamental plants, which is why it constitutes a powerful market for our country. It is for this reason that since its creation in 1991, the Ciego de Avila Bioplant Center has been working on the national and international propagation and commercialization of ornamental species of high commercial value, among which are found. Fruit trees: Within the plantation crops, they are the fruit trees of the plants with the greatest interest for micropropagation laboratories. Phytosanitary sanitation and the introduction of new varieties are the most important aspects when working with fruit trees. In the Cuban fruit industry; bananas, citrus fruits and pineapple are among the most important areas where micropropagation plays an essential role.

The micropropagation of plants requires the periodic transfer of the culture to fresh medium due to the depletion and / or alteration of the nutrients, as well as the continued growth or proliferation of the tissue, which exceeds the capacity of the culture flask. Cultures are generally kept in individual flasks and transferred to fresh medium within four to six weeks. The use of the liquid medium for in vitro propagation has some advantages and is considered an ideal technique for mass propagation of plants, because it reduces handling and is a prerequisite for the automation of the process. Some alternative micropropagation systems, with the use of liquid medium, have been developed with the purpose of automating the process and consequently reducing costs. More recently, Teisson and Alvard (1995) developed an apparatus for the micropropagation of plants from the modification of a 250 mL capacity Nalgene filtration unit whose trade name is RITA. In Israel, a group of researchers have designed a disposable bioreactor for organ culture that is currently marketed by OSMOTEK. In Cuba, since the development of the first semi-automated temporary immersion system in 1997, developed by a team of researchers from the Bioplant Center, research has been carried out on the application of this technique in the proliferation of meristems of various species of agricultural interest. , ornamental and forestry. Technological description of the Temporary Immersion Bioreactor (BIT) designed at the Bioplant Center. The system consists of two translucent autoclaveable plastic containers, autoclavable silicone hoses, 0.2 hydrophobic filters, solenoid valves and an air compressor. One bottle is the culture glass for the explants and the other is the container for the culture medium. Both bottles communicate through silicone hoses. Sterility conditions are achieved through the use of 0.2 diameter hydrophobic filters. The culture batteries (consisting of a flask for the culture of the explants and a flask for the storage of the medium) are placed on aluminum shelves measuring 0.7 m wide x 2.3 m long x 2.5 m high. The air distribution from the compressor to the bottles is done through a PVC connection. Each floor on the shelf has a panel of lights (fluorescent white) that guarantee a DFFF between 30 and 50 * mol. m-2. s-1. The frequency and the time of immersion are controlled through a programmable automaton. According to the programmed time, a valve is opened and the air coming from the compressor forces the culture medium towards the bottle containing the explants. During the immersion period, the air flow allows the medium to bubble, removes the explants, and changes the atmosphere within the culture vessel. After the immersion time, a second valve is activated and the medium is returned to the storage container. By means of the automatic controller the frequency and the immersion time is regulated. Results by cultures obtained with the BIT. Comparison with other micropropagation methods The BIT has two possibilities of application: for obtaining explants and their subsequent proliferation in conventional micropropagation flasks or for obtaining shoots suitable for ex vitro rooting and acclimatization. The following table summarizes the multiplication coefficients that have been achieved in the different crops with the use of the BIT. Cultivation Variety Microp. Conv. Inm. Temp. Cultivation Variety Microp. Conv. Inm. Temp. Smooth cayenne pineapple 8.0 68.8 Malanga INIVIT 3.0 10.44 MD2 5.8 26.8 Mexico 1 2.8 7.71 Sugar cane C 91-301 3.7 34.1 Banana FHIA-18 3.8 7.4 C120-78 4.1 58.0 FHIA-01 3.4 10.4 C1051-73 3.9 30.2 Big dwarf 4.0 16.6 C323-68 4.3 39.5 Syngonium W. butterfly 7.3 28.0 C85-212 3.8 31.6 Pixie 2.2 18.4 Tropical Anthurium 4.0 79.8 Spathyphyllum Sensaion 3.7 61.5 Miniature Rose 3.5 15.9 Phylodendrom Xanadu 2.0 102.9 Temporary Immersion Bioreactor (BIT) graphic design. Components. Description of the automatic temporary immersion system. a) A solenoid valve opens and the air pressure from the compressor pushes the culture medium into the jar containing the plants. b) Waiting bath time. c) After a selected period of time, a second valve opens and the air pressure returns the culture medium to the medium reservoir bottle. Air compressor. Solenoid valve. Hydrophobic filters (0.2 µm). Our specialists provide advice on the assembly, commissioning and operation of Temporary Immersion Bioreactors. We have more than twenty technologies for different crops of agricultural, ornamental and forestry interest, while commissioned research is carried out for crops of specific interest. This technology is especially useful for the rapid proliferation of new varieties.

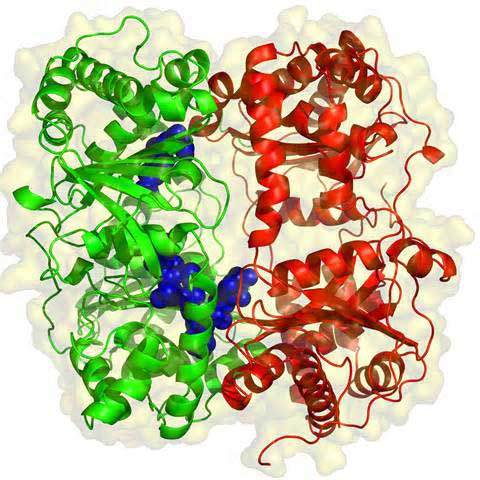

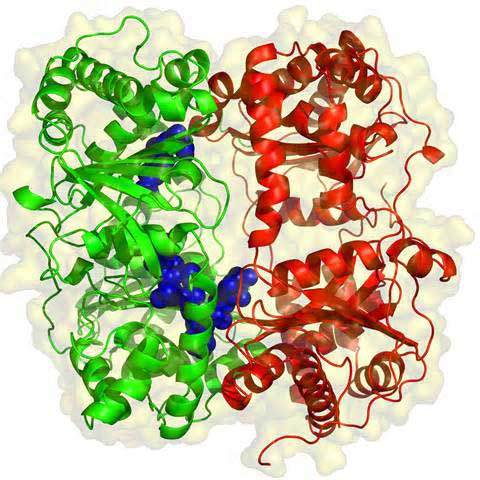

The production of proteases, on a world scale, represents 38% of the total volume of commercialized enzymes. Bromelain (EC 3.4.22.32), of preferential use, due to its broad specificity of action, has been isolated and purified from plants of the Bromeliaceae family. An original and economical technology (Cuban Patent C12N 9/50) was designed and optimized, in which by protecting the? SH groups of the active center of the enzyme and the proper manipulation of the medium (nature, pH, ionic strength), high yields are achieved in terms of protein and specific activity. The functional characterization of the preparation made it possible to evaluate the optimal kinetic parameters of activity. Its operational and conservation stability was demonstrated. The purification of the enzyme by a combination of chromatographic methods allowed its molecular characterization. The process is repeatable and easy to scale, which was evidenced by achieving yields of 15 to 25 g of product / kg of stems at an industrial level. Advantages of the new technology: Simple and easy to scale extraction process that only requires the addition of two reagents in small quantities. The extraction conditions allow the enzyme to be obtained with the -SH groups of the active center protected and at a pH that guarantees stability, reducing proteolysis. The costs of fresh material are minimal, as it is used as a source for the extraction of pineapple stems from fields to be demolished or as a by-product of the in vitro propagation methods of pineapple in Temporary Immersion Systems. Product with different degrees of purity can be obtained. The EC (crude extract) that are used in the Biotechnology Industry to obtain culture media. The higher purity preparations are used in the Medical Pharmaceutical industry with potential for use as antitumor.